Carbon pipes have the characteristics of easy threading and good flexibility

Carbon tubes are plastic products made by squeezing raw materials and play an important role in industrial production. The demand in related industries is high, which has led to an increasing number of manufacturers producing such products in the market. However, how much do we know about their own performance? Let the editor test everyone.

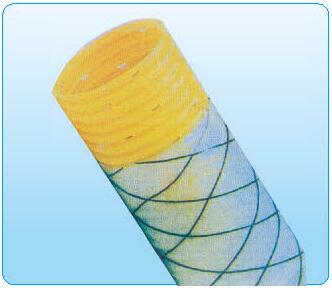

Carbon tube is made of high-grade high-density polyethylene as the main material, with carbon added and modified color masterbatch directly extruded through modern technology. Due to the addition of carbon in the raw material, the inner wall of the tube is very smooth. Compared with ordinary tubes, carbon tube can effectively reduce the friction on wires and optical cables, and the direct friction coefficient is reduced by 60% compared to ordinary tubes. In addition, due to the excellent thermal conductivity and heat dissipation ability of carbon, it can provide a good ventilation and heat dissipation space for the cables in the pipes, effectively extending the service life of wires and optical cables, reducing maintenance costs, and making it an ideal product for the operation cost of the power communication department.

With the development of society and the improvement of technology, the application of carbon pipes is very extensive, which is related to its own characteristics. The following are the characteristics of carbon pipes.

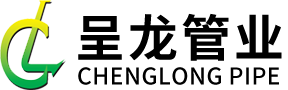

1. Good flexibility: It has a special threaded shape and can bend freely around obstacles, making construction convenient.

2. Single length: The length of a single piece is determined by the user at will to reduce the number of connecting ports, making construction fast and maintenance convenient.

3. Lightweight: Shorter than cement pipes, fixed length cast iron pipes, steel pipes, and fixed length PVC pipes are lightweight, easy to transport, and reduce labor intensity.

4. High strength: With a special threaded physical shape, it has high compressive strength and will not deform under heavy pressure underground.

5. Corrosion resistance n: Good acid, salt, and alkaline resistance, with a long service life.

6. Safety: It has strong impact resistance, disturbance resistance, and high strength, and is safe even in the event of earthquakes or abnormal ground subsidence.

7. Easy threading: The inner and outer surfaces are smooth, the friction coefficient is small, and there is a lead wire inside the pipe, making threading very convenient.

8. High reliability: After strict inspection and appraisal by relevant national departments, it meets technical standards and is a reliable replacement product.

9. Low construction cost: Taking into account the above advantages, it has fast construction, short construction period, few interfaces, and high economic benefits.

These excellent characteristics make carbon nanotubes widely used in geographic engineering to beautify streets and replace utility poles; Urban street lamp buried engineering; Residential construction; Parks and golf courses; Industrial zone construction; Agricultural drainage and irrigation and water conservancy engineering; Urban network renovation, buried cable conduits, telecommunications cables, highways, substations, water conservancy projects, etc.

I believe that after reading the detailed introduction by the editor, I have a deeper understanding of carbon pipes. In fact, the demand for them in the industry is constantly increasing, and we are also increasing the difficulty in choosing them. The quality produced by manufacturers cannot be measured. Therefore, I believe that our company can bring you better choices.