The editor will briefly describe the four structural characteristics of cable clamps for you!

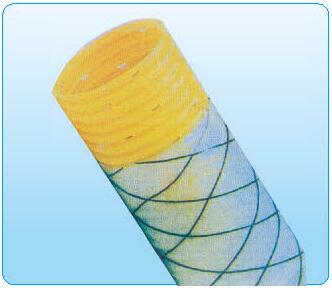

As the name suggests, cable clamps are used to fix cables and prevent them from fluctuating due to external factors. The material of the clamp is generally a metal product that has undergone anti-corrosion treatment. It generally has multiple advantages such as corrosion resistance, light weight, and simple structure. Its structure generally consists of four parts. Today, the editor will take you to understand which three parts are there?

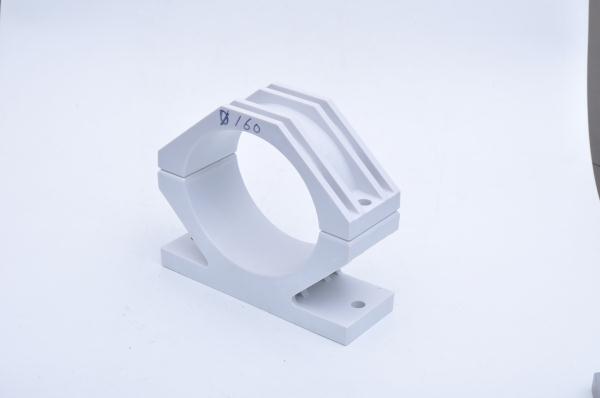

The upper part of a rubber base is curved, with a radius consistent with the cable radius, which can protect the cable in a large area. Traditional fixtures, due to their rigid base structure, are prone to damaging cables when the base gasket falls off or is not in place. This problem is most likely to occur during the cable construction phase. The main reason for this is that the foot pads on the base are easily detached due to construction impact, and cables placed on the base without foot pads are easily damaged. During cable operation, due to the long-term vibration caused by electrical forces, the rigid base is also prone to cable damage; Secondly, the base is prone to angle deviation due to its lack of fixation. When the cable is placed on a rigid base with deviation, it is more susceptible to damage from the base's rigid arc angle and edge. The rubber base produced by our company cannot be deflected or has rigid corner edges, and there is no condition for damaging the cable.

The bottom of the second base is equipped with U-shaped edges and right angle edges. Before laying out the cable, the base can be automatically locked onto the cable support, effectively preventing the occurrence of construction rework caused by the detachment of the fixture base. The traditional fixture base is flat, and due to the inability to be fixed to the cable support in advance, it often falls off due to vibration, friction, and other reasons. Moreover, it is not easy to detect the detachment of the base. Only when the three-phase cables are fully laid out and the experiment is completed and the bolt fixing fixture process is entered can the base detachment be detected, and rework is forced at this time. Even worse, when the cable is a 220KV large cross-section model, due to the heavy weight of the cable, it cannot be lifted manually, and lifting tools such as chain blockers must be used to lift the cable and place the clamp base. After investigation, this situation has occurred from time to time, causing significant project delays and cost increases for construction companies; The on-site workers have strongly responded to this. Our company has developed a new type of cable clamp base after repeated improvements, which can completely prevent such problems from occurring.

The reserved holes at both ends of the three bases are elliptical, which can meet the requirements of various errors in the distance between cable support holes and facilitate the installation of bolts. The traditional fixture base is a rigid structure with circular reserved holes at both ends without any adjustment of hole spacing error. Slight errors during bolt threading can make it difficult or impossible for the bolt to pass through, and even more so, it may require re drilling on the bracket to pass through the bolt. This kind of problem often occurs during the installation process of the project, causing certain economic and schedule losses to the project. Our company's new fixture completely solves this problem.

The thickness of the arc bottom of the four bases is basically the same as the thickness of the adjacent bracket gasket, which can ensure that the cable is evenly stressed and not suspended in the adjacent bracket. The traditional fixture base is a rigid structure, with a thicker arc bottom and a thicker rubber pad, resulting in a total height far greater than the thickness of adjacent bracket rubber pads. This causes one to two adjacent bracket cables to be suspended, causing the pressure that should have been borne jointly by several brackets to be borne by one bracket of the fixed fixture. This will inevitably increase shear stress damage to the cable insulation material and pose a safety hazard to the normal operation of the cable after being charged. And our company's fixtures do not have such problems.

A complete cable clamp consists of two main parts: rubber and metal. Rubber is used for insulation, while metal plays a major fixing role due to its high strength. Alright, that's all for today's introduction. If you need the above products, please feel free to contact us!